We Create Robotic Systems for the Jewelry Industry

THINK MODULAR! THINK FLEXIBLE!

Our Systems are Designed to Fit the Jewelry Manufacturing Process!

- Need to Run your FRE Systems With Lights-Out Manufacturing Options? CONTACT US!

- Backlogged and Bottleneck Manufacturing? CONTACT US!

- High Turnover Costs? CONTACT US!

- Low First Pass Yield? CONTACT US!

Welcome to FRE

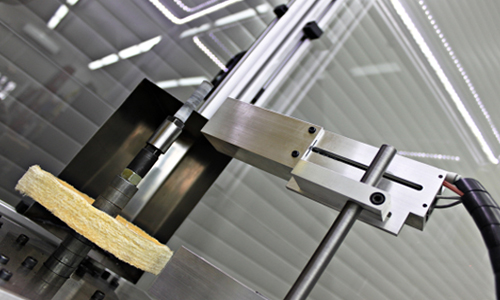

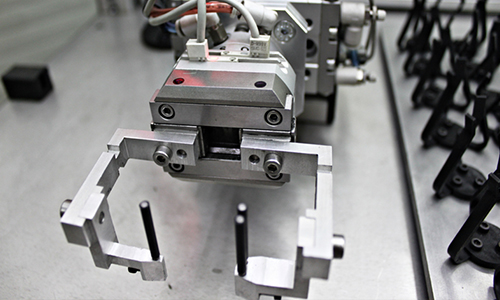

Flexible Robotic Environment (FRE) is a full-service engineering firm specializing in automated jewelry processing systems. In business for over 20 years, we have developed a full line of products to process and polish rings, pendants, studs and bracelets, with custom and expandable solutions to meet your needs

Why choose a FRE system?

YES! IT IS HERE!

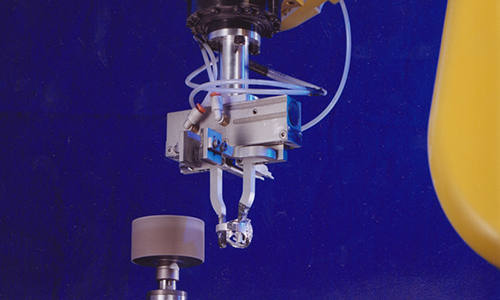

Robotic systems intended only for the jewelry industry! Patented hardware and software solutions are creating high product quality with high savings.

MORE EFFICIENT

Systems do not take any coffee or any other breaks. Systems are operated by already employed working personnel who dedicate only up to 1 hour of their working day to ensure full shift production of this unit.

USER ORIENTED

Our systems are user friendly and do not require knowledge of robot programming. Installation and initial training are based on “plug and play” methodology.

SAVE ON LABOR COSTS

Depending on part styles, robotic polishing units will significantly streamline your polishing department while providing reduction in worker’s comp costs. In addition, systems will reduce production bottle necks, while increasing production volumes and flows.

SAVE ON LOGISTICS

Our products will process jewelry with multitude of features. As a result the user may save on cleaning times and on operation preparation times.

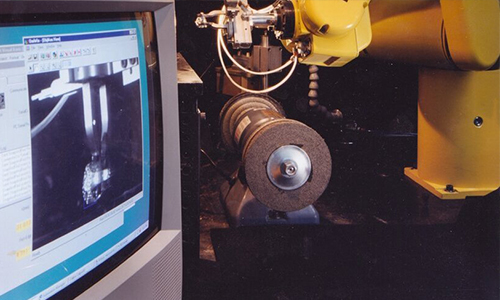

CONTROL YOUR MANUFACTURING PROCESS

Our systems can be used at various times within your manufacturing and for a variety of operations. User can deploy our robotic unit for long or short orders depending on the immediate manufacturing needs. System automatically adapts to size and shape variations of a jewelry piece.

CONTROL PRECIOUS METAL SCRAP

Unit is completely enclosed, and it operates with a dedicated dust collector thus providing high precious metal collecting capabilities. In addition, our system deploys force control during the polishing process thus providing consistent material removal regardless of the shape and size of the surface.

INDUSTRY 4.0 READY

Our systems come with IIOT capabilities and ready for edge-software development. Such characteristics allow the customer to integrate within Industry 4.0 advanced manufacturing settings.

QUALITY ON DEMAND, WITH MINIMAL MATERIAL LOSS

Enjoy the efficiency and speed of patented user-friendly software! Your production process will now be based on your own and defined processing recipes that provide structure to your product. This ensures consistent quality!

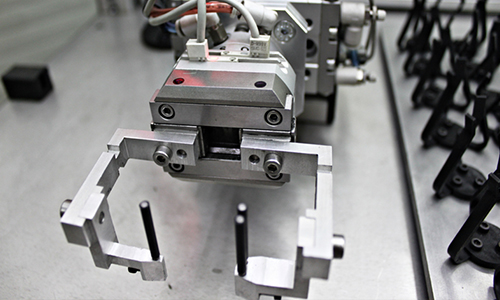

VERSATILITY

With a series of features and options, our product lines will enable processing of a variety of jewelry products. Systems can also be configured for machine tending operations and for mold reconditioning.

SAVE ON LOGISTICS

Our systems come with IIOT capabilities and ready for edge-software development. Such characteristics allow the customer to integrate within Industry 4.0 advanced manufacturing settings.

QUALITY ON DEMAND, WITH MINIMAL MATERIAL LOSS

Enjoy the efficiency and speed of patented user-friendly software! Your production process will now be based on your own and defined processing recipes that provide structure to your product. This ensures consistent quality!