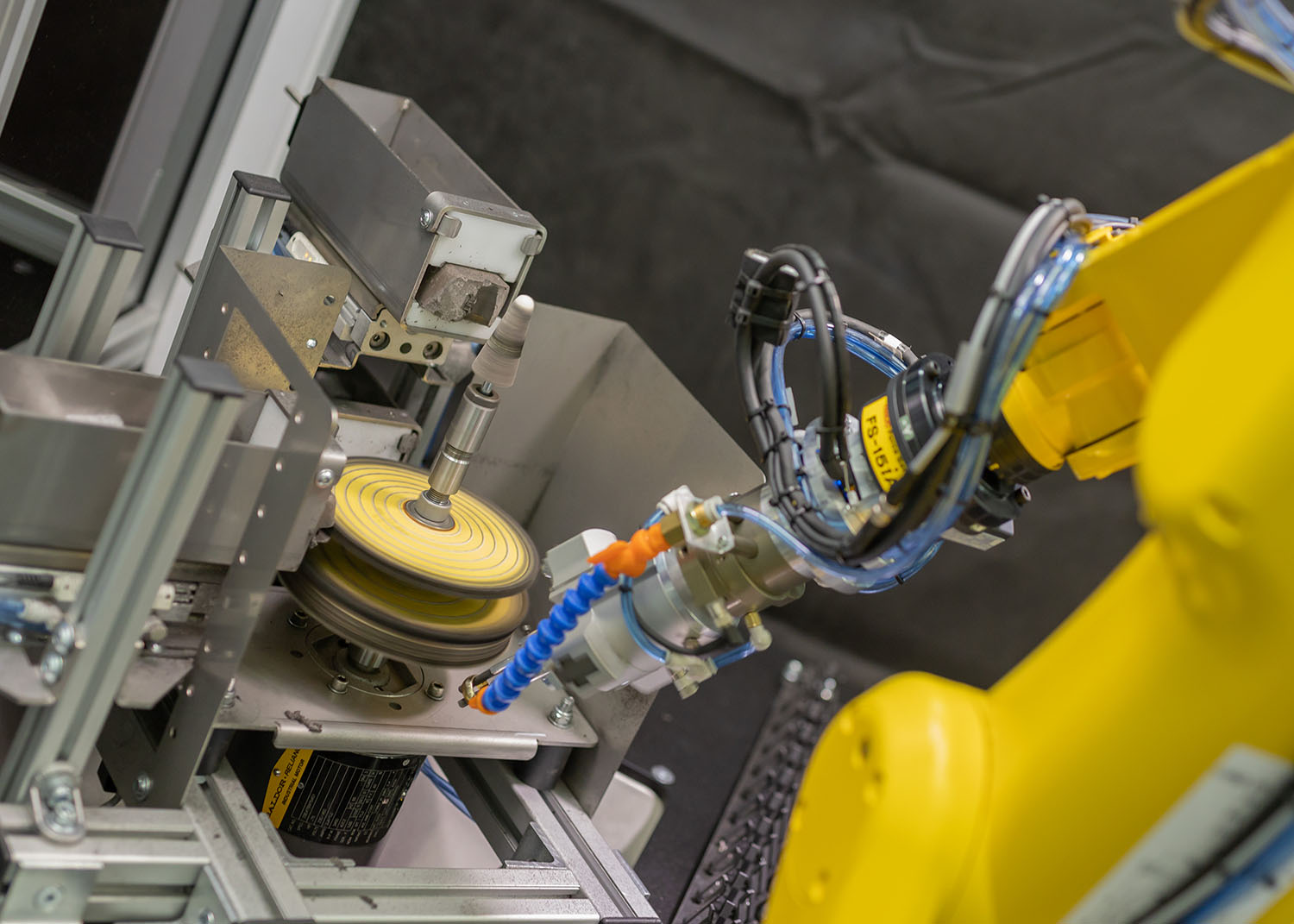

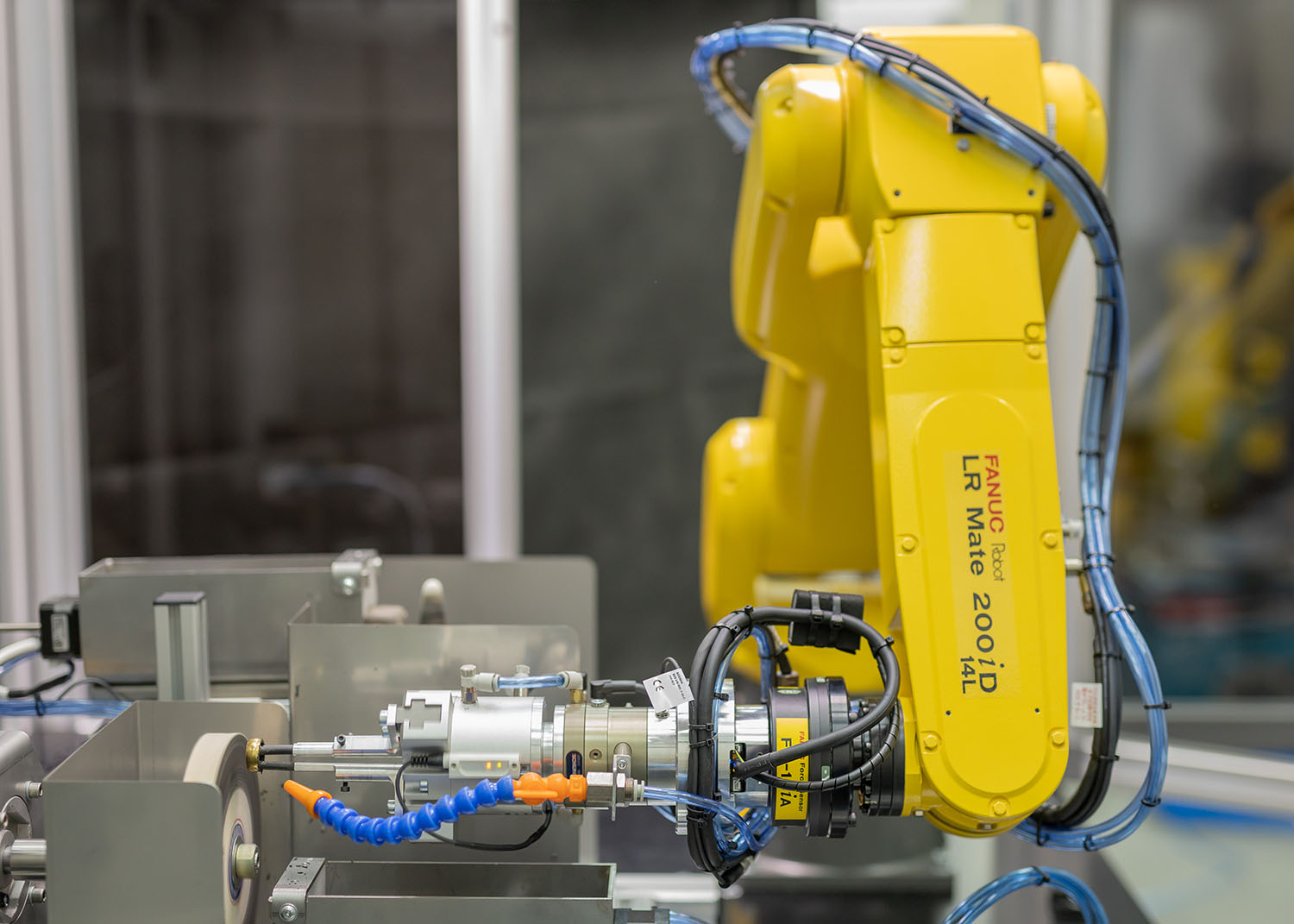

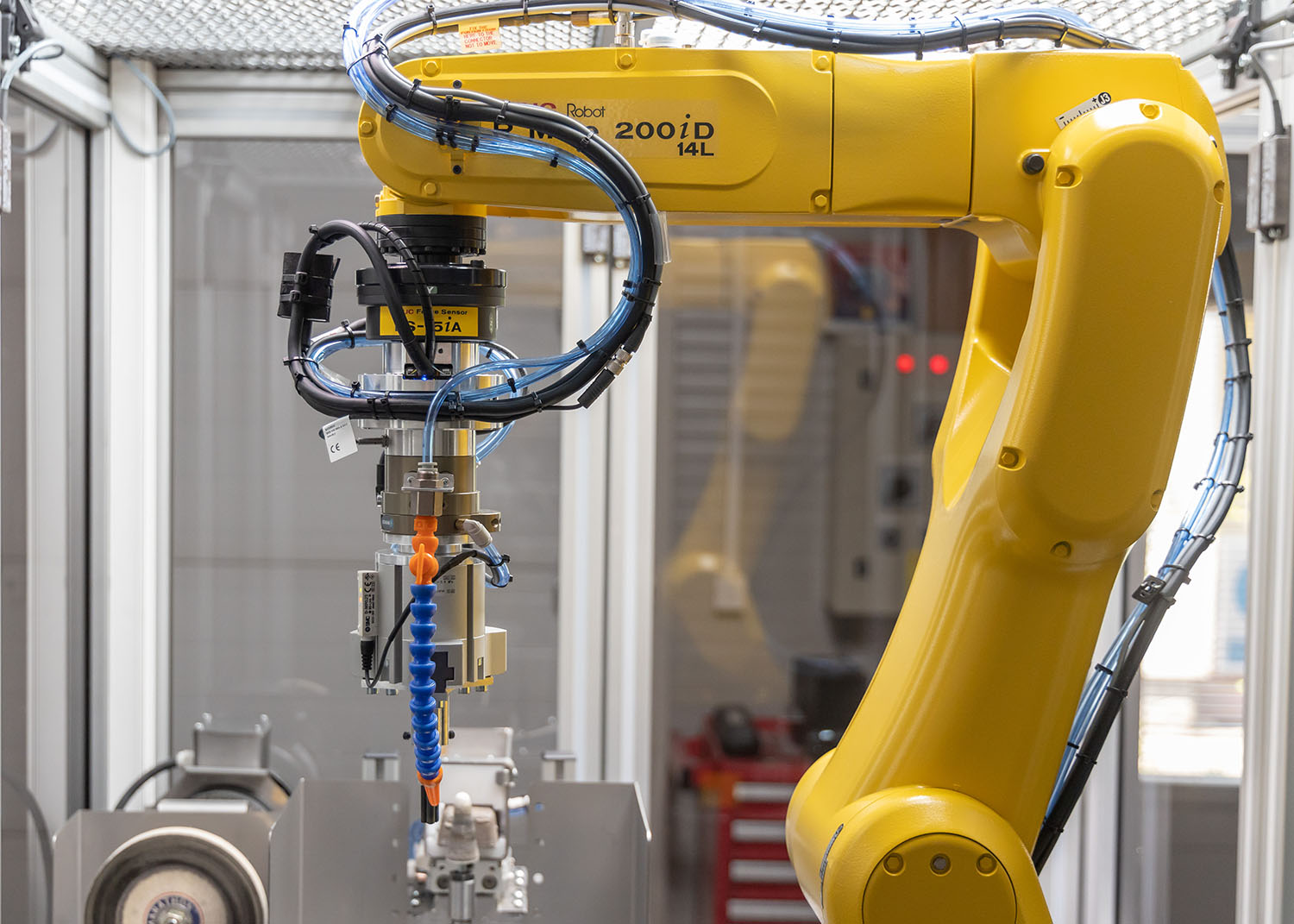

Ring Polishing Robotic Systems (VDK-1250 Series)

The VDK-1250 automated ring product line enables polishing, buffing, and sanding of rings. All system configurations summarized below, are designed for specific production needs while ensuring high quality. Systems differ in flexibility, capacities, and process capabilities.

VDK-1250-BASE

This unit is designed to help with production fluctuation and mass ring production needs. Base provides inside/outside polishing operations. System’s ring style database can accept up to 100 different styles.

VDK-1250-C

This CLASSIC unit performs pre-polishing, polishing and buffing operations on almost unlimited style and size variations. It provides a capability to change over 30 different polishing parameters dictated by a style.

VDK-1250-G/SP/EG

This VDK-1250-G/SP/EG unit is a ring grinding unit that may be configured as a dedicated system for sprue removal and for inside/outside grinding operations. It has multiple sanding tools for sprue removal.

VDK-1250-L

VDK-1250-L is a ring lapping unit featuring a safe and capable lapping environment. Capability to accept externally created MoDusCAM© path files that will allow for lapping of complex ring shapes.

VDK-1250-F

VDK-1250-F is a FLEXIBLE unit that allows the user to use multiple spindle + configurable rouge (SCR) modules and compose a system with respect to specific customer technology needs.